How to operate the frequency for the pump motor?

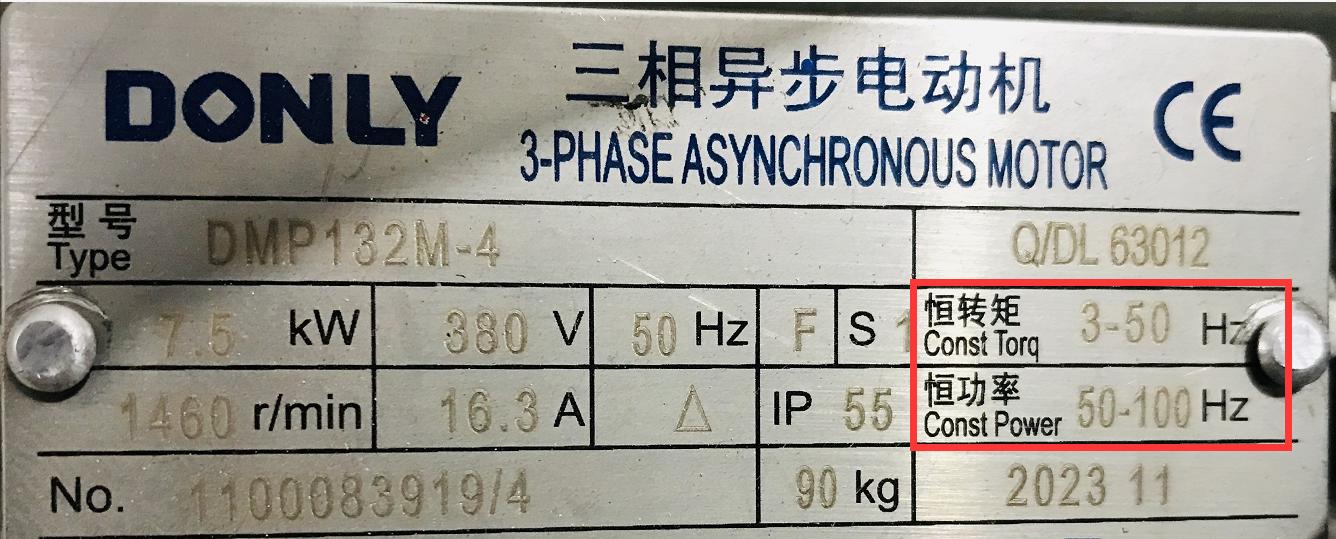

On the motor nameplate provided by BONVE Rotary Lobe Pump, we can see two frequency ranges:

1. Constant Torque Frequency Range: 5-50Hz

2. Constant Power Frequency Range: 50-100Hz

How to understand them and use them into your operating?

Constant Torque Frequency Range means that the motor can provide a stable output torque throughout the entire frequency range. This indicates that the output torque of the motor remains unchanged when adjusting the frequency. This is particularly important for rotarylobepumps when handling fluids with increased viscosity due to temperature decrease, as higher viscosity requires lower suitable speeds.

Constant Power Frequency Range means that the output power of the motor remains constant across the entire frequency range. Regardless of the adjusted frequency (speed), the motor maintains a consistent output power. In rotarylobepump applications, constant power frequency allows for better dynamic response to meet the flow rate and pressure requirements when handling low-viscosity fluids, especially during CIP (Cleaning-in-Place) or water washing processes.

Usually, our customers ask: "In the case of constant torque, if the frequency decreases, does the power reduction mean the pump cannot operate normally?"

This is a valid question. Indeed, reducing the frequency will result in a decrease in power. Power reduction means that the mechanical torque output of the motor also decreases.

Within the frequency range of a variable frequency motor, the motor can output the same torque at different frequencies, which is known as the constant torque frequency range. When the frequency decreases, the motor torque remains relatively constant, but the power decreases because power is directly proportional to torque multiplied by angular velocity (Power = Torque × Angular velocity).

When the frequency reduces to a certain extent, the power reduction may prevent the motor from providing sufficient force to drive the pump load, particularly for larger loads or high resistance. Hence, if the frequency is too low, the motor may fail to drive the rotary pump or generate sufficient output power, resulting in the pump's inability to operate properly.

Therefore, during the pump selection process, we carefully inquire about the operating temperature and viscosity from the customers. Based on the actual load requirements and the motor's frequency range, we choose appropriate speeds and power to ensure that the motor can provide sufficient torque and power to meet the pump's load requirements. If you are interested to know details about the Rotary Lobe Pump, pls click here.

Regarding the constant power frequency range of 50-100Hz, is it better to operate at higher frequencies? Can a small pump be used as a large pump? Absolutely not. Running the pump at excessively high frequencies can alter the hydraulic characteristics of the pump, leading to issues such as cavitation, increased pressure pulsation, noise, and vibration. These factors can negatively affect the pump's stability, performance, and lifespan.

We welcome your comments on frequency operating if have any different opinions. Talk to me via cathy@bonvepumps.com or WhatsApp: 0086-13616639068.

评论

发表评论