Rotary lobe pump working principle and structure - Bonvepumps.com

- What is a rotary lobe pump?

- How rotary lobe pumps work?

- Rotary lobe pumps parts

- Lobes types and why different need?

- Construction material of lobe pumps

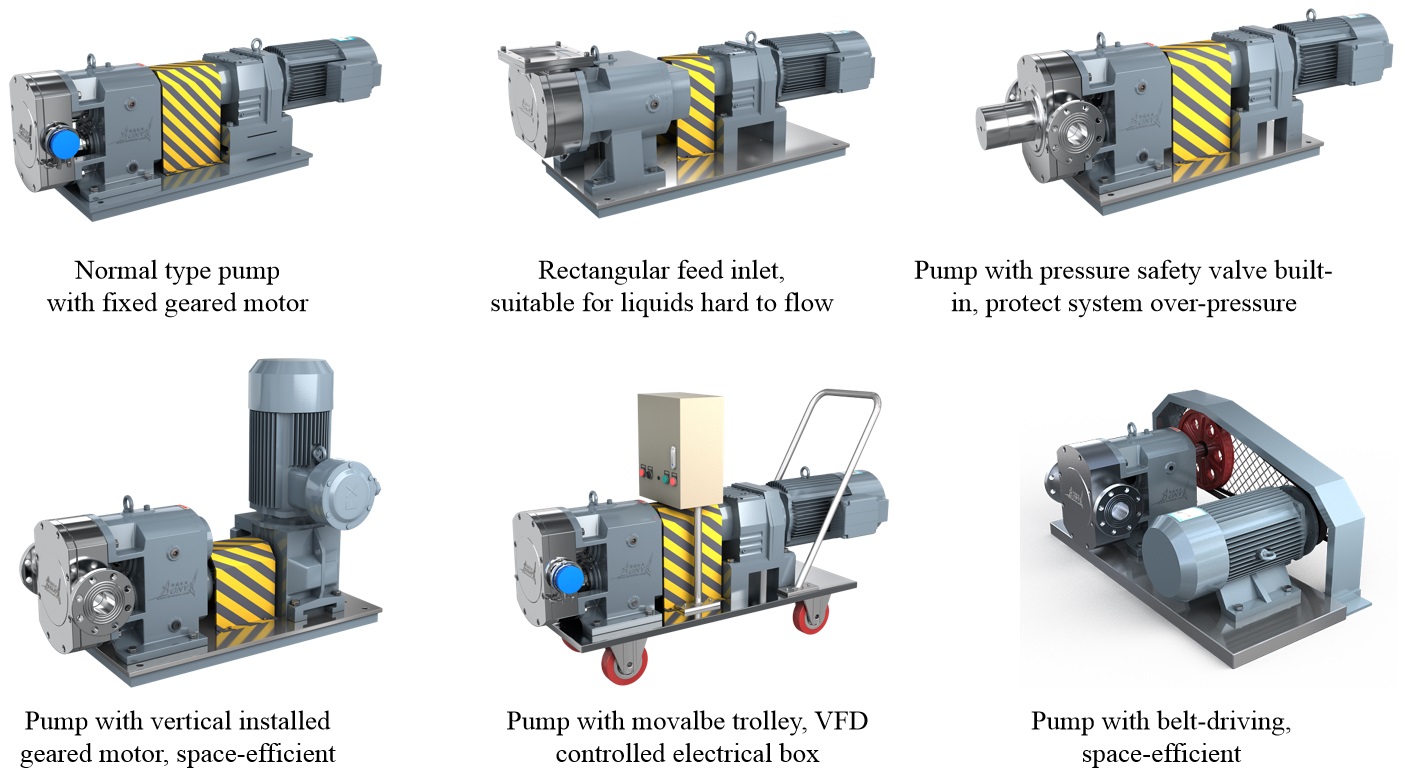

- Configuration Options of lobe pumps

What is a rotary lobe pump?

Rotary Lobe Pumps are positive displacement pumps able to transferring liquids products,especially for high viscosity, high solidand arefeatured aslow shearing. Gentletransferringmakes them popularused in food, cosmetics and industrial chemicalproducers. No damage to the pumped products.

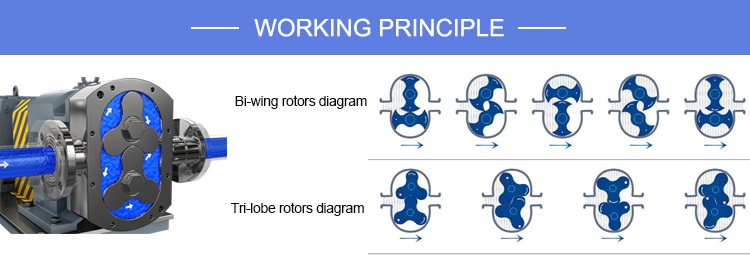

How rotary lobe pumps work?

Rotary lobe pump working principle is easy to understand. They basically consist of two lobe rotors, which rotate synchronously driven by a pair of synchronous gears in the gearbox. The rotors are driven by the main shaft and sub-shaft to rotate in a synchronous reverse direction, which changes the pump capacity, builds up high vacuum and discharge pressure, thus an efficient pumping is formed.

Parts of rotary lobe pumps

The main parts are including rotors, pump cavity, mechanical seal, shaft, bearings and gears. They are processed by CNC to ensure high precision fabrication.

Constructionmaterials of rotary lobe pumps, but are not limited to:

Product contact metal parts: stainless steel AISI 316, 316L, duplex, 904L

Mechanical Shaft Seals: Tungsten carbide, Silicon carbide

Sealing Materials of O-rings: Viton, EPDM, FFKM

Configuration of rotary lobe pumps, normal types for Bonve brand.

Lobes types and why different need

According to the different product transfer, manufacturers have different lobes design to make sure an efficient feeding and no failure, such as single-wing, bi-wing, tri-lobe, four-impeller, eight or twelve-impeller lobes. See below diagram which shows each lobes type application.

评论

发表评论