Difference Between Homogenizer Mixing Pump and Colloid Mill | Bonvepumps.com

Both colloid mill and homogenizer mixing pump can shear, emulsify, disperse, and mix materials, but in fact, colloid mill and homogenizer mixing pump are two kinds of equipment based on the principle, structure, and application.

Colloid mill is a kind of grinding equipment, suitable for materials with higher viscosity and larger particles. The working principle of the colloid mill is that the motor drives the rotor and the stator to rotate at a relatively high speed. When the processed material passes through the gap between the stator and the rotor, it is subjected to strong shearing force, frictional force, high-frequency oscillation and other physical effects. The material is effectively emulsified, dispersed and crushed to achieve the effect of fine crushing of the material.

Emulsification pump is a kind of emulsification equipment, which is suitable for materials with small particles. The working principle of the emulsification pump is that the material undergoes a series of processes such as strong shearing, impact and turbulence between the homogenizer rotor and the stator that rotate at a high speed, so that the material can withstand hundreds of thousands per minute in the narrow gap between the stator and the rotor. Times of hydraulic shear. The combined effects of centrifugal extrusion, impact and tearing can instantly evenly disperse and emulsify. After high-frequency cyclic reciprocation, high-quality products with no bubbles, fineness and stability are obtained.

From the above point of view, the difference between the two in terms of the refinement effect, the mixed homogeneous emulsification pump is better than the colloid mill. Generally, in many occasions, the colloid mill is used in the front of the emulsification pump or in the high In the case of viscosity, colloid mills are often used for refinement when there are many solid substances. Therefore, when choosing colloid mill and emulsification equipment, you still have to refer to your own production materials.

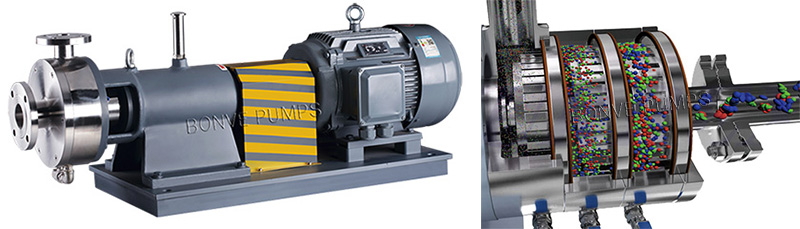

Bonve homogenizer mixing pump’s working chamber is composed of a total if 12 layers of three-stage rotor and stator. Proceed products are dispersed, refined and emulsified by the rotor and stator in stages. The pump is an high efficiency ultra-fine homogeneous pump with mixing, dispersion, breaking, dissolution, refinery, homogenization, emulsifying and transporting. The sealing of Bonve homogenizer mixing pump can be either double face or single face according to the properties of the processed materials. It also can have heating insulation or cooling device if required by the users.

Bonve homogenizer mixing pump is suitable for large and medium batch continuous online production or cyclic processing production process.

Email:trade@bonvepumps.com

评论

发表评论