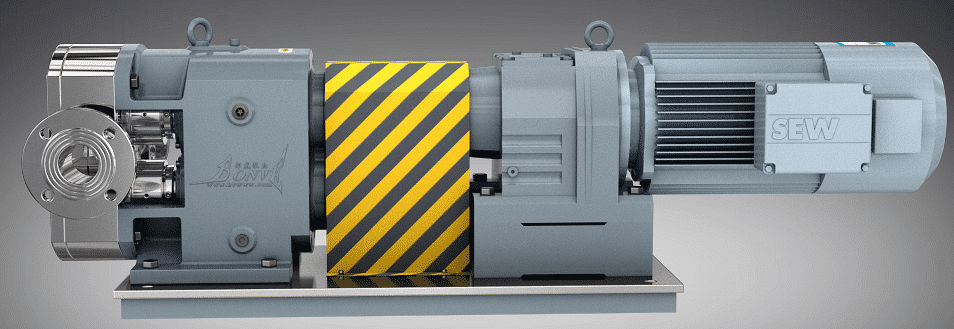

Bonve 4th generation rotary lobe pump in 2020

Bonve rotary lobe pumps are designed based on the exploration of more than 3,000 fluids in various industries. They are particularly, effectively pumping for high viscosity, high solids and corrosive fluids. For more than a decade,Bonve rotary lobe pumps have been developed to the 4thgeneration. The extensive application of Bonve 4thgeneration pumps in various fields benefits from innovative structural design and large experience accumulation. Pump shows its talent on low pulsation, high pressure, and efficient transmission, which extends the service life of the pump and reduces the maintenance costs. The new generation pump has the following features:

Strong interchangeability

Interchangeable rotors, one pump multi-purpose

Targeted seal for specific application, ensure zero leakage.

Strong stability

Six bearings with separate arrangement, high balance.

Adjustable seal ring extends shaft life.

Axis key synchronous adjustment, no rotor collision problem.

Low maintenance

Maintenance in place, easy cleaning.

Fewer wearing parts, low maintenance and long life.

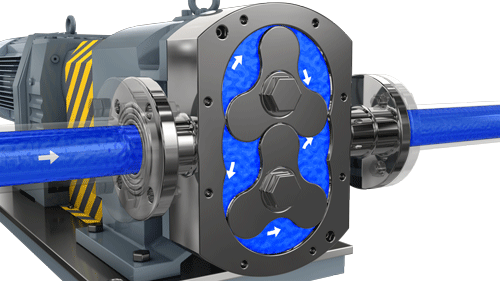

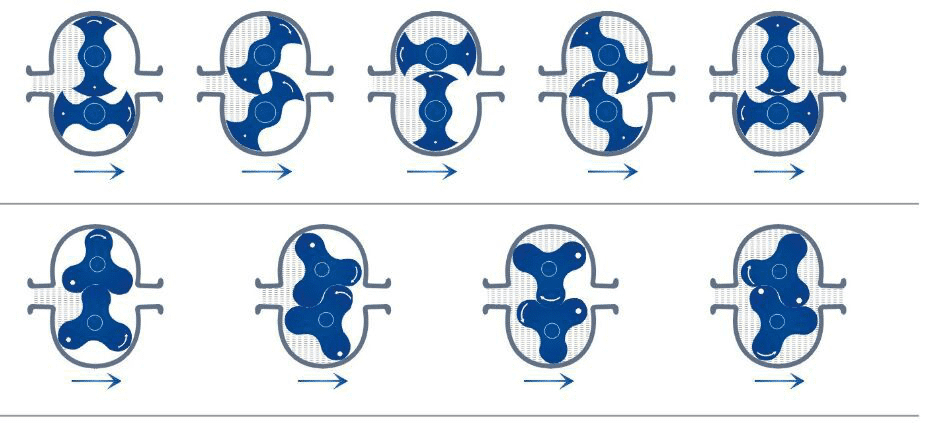

WORKING PRINCIPLE

Bonve lobe pumps basically consist of two lobe rotors, which rotate synchronously driven by a pair of synchronous gears in the gearbox. The rotors are driven by the main shaft and sub-shaft to rotate in a synchronous reverse direction, which changes the pump capacity, builds up high vacuum and discharge pressure, thus an efficient pumping is formed. Gap is kept between the rotors and between the pump casing, no friction, long life, no damage, no physical and chemical reaction to the pumped products.

STRUCTURE FEATURES

Rotor:Perfectly seals and isolates the inlet and outlet of the pump. The vacuum degree of the pump is as high as -0.095MPA. Rotor material and type can be selected according to the characteristics of the conveying medium.

Shaft:Processed by the CNC machining, equipped with high precision, high bending strength and strong wear resistance.

Pump chamber:Sealed by a pump cover that can be quickly opened, enabling quick maintenance of the pump. Processed strictly in accordance with the US 3A standard to meet the requirements of CIP and SIP.

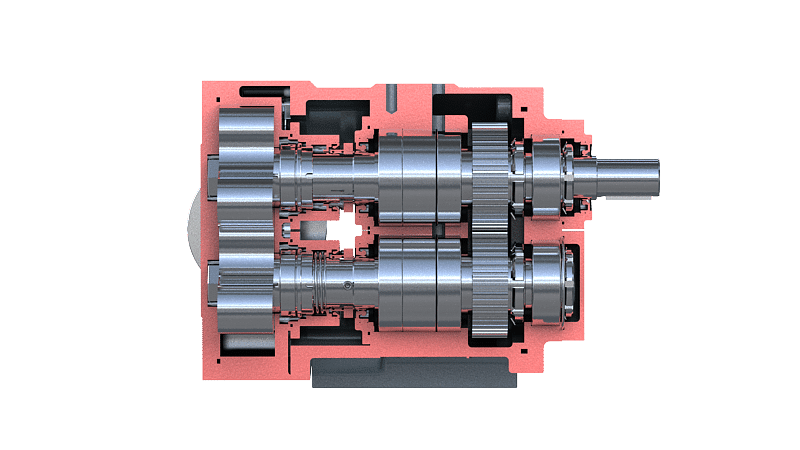

Gears:High-precision, high-standard synchronous gears have good meshability, smooth transmission, low noise, and excellent load carrying capacity.

Mechanical seal:According to the different characteristics of the medium, the mechanical seal type and material are used to ensure zero leakage and no pollution.

Bearings:Six bearings in a separate arrangement increase the concentricity of the pump operation, reduce the bearing capacity of the shaft and make the structure more stable, thereby increasing the service life of the shaft and the mechanical seal.

Gear box:Processed by imported four-axis linkage machining center with high accuracy, high concentricity and strong versatility.

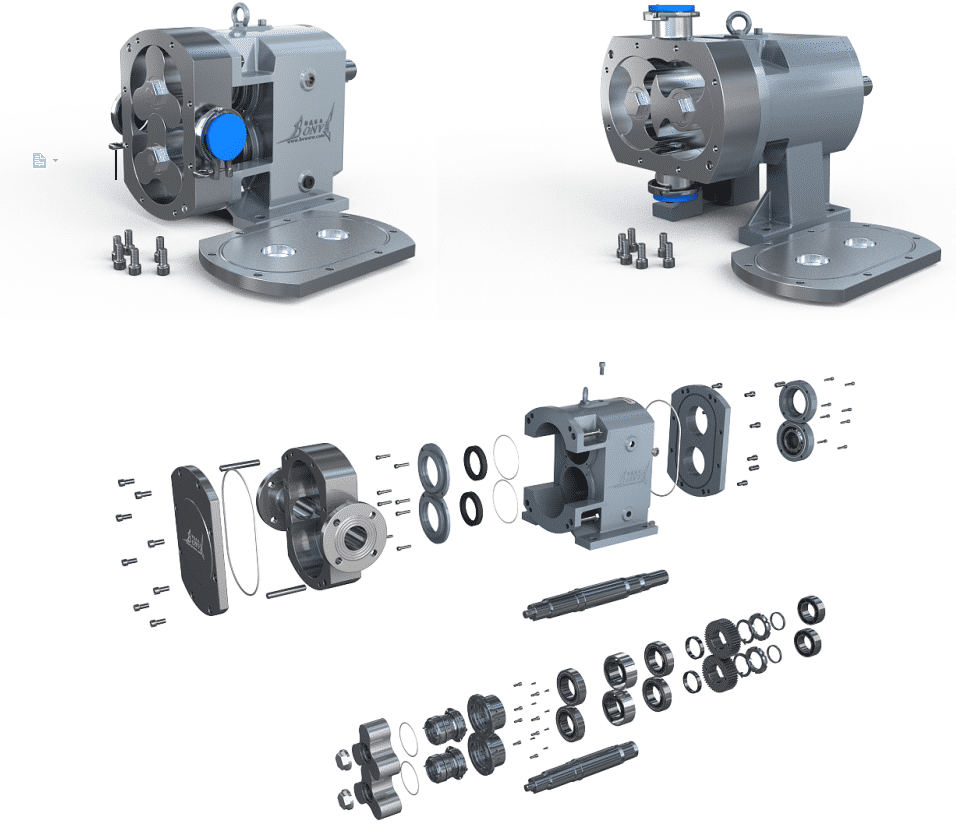

BARE SHAFT PUMP STRUCTURE

BONVE bare shaft pump is mainly composed of rotor, chamber, mechanical seal, gear box, gear and driving shaft. All these core components are processed by CNC.

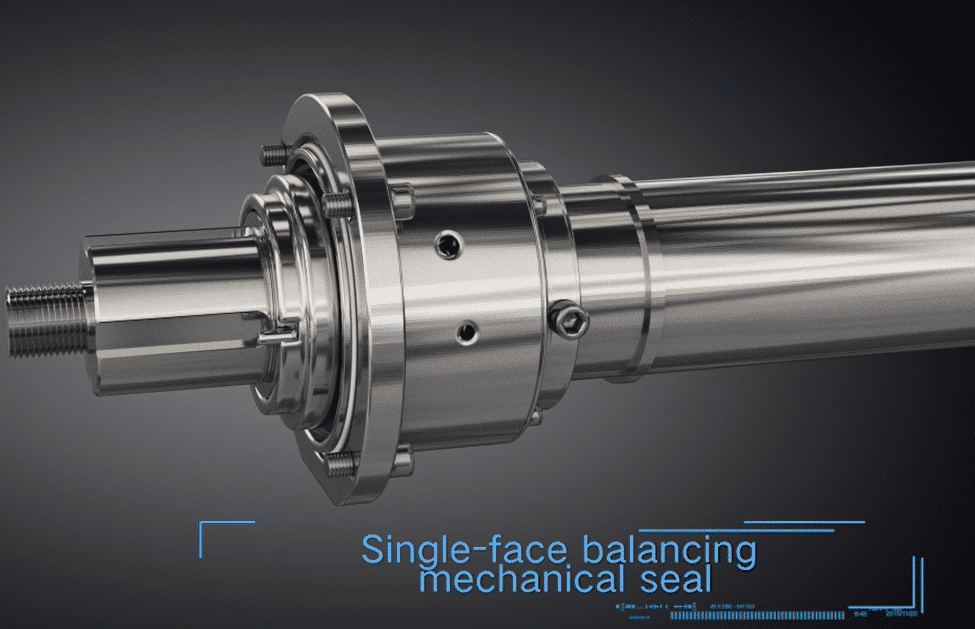

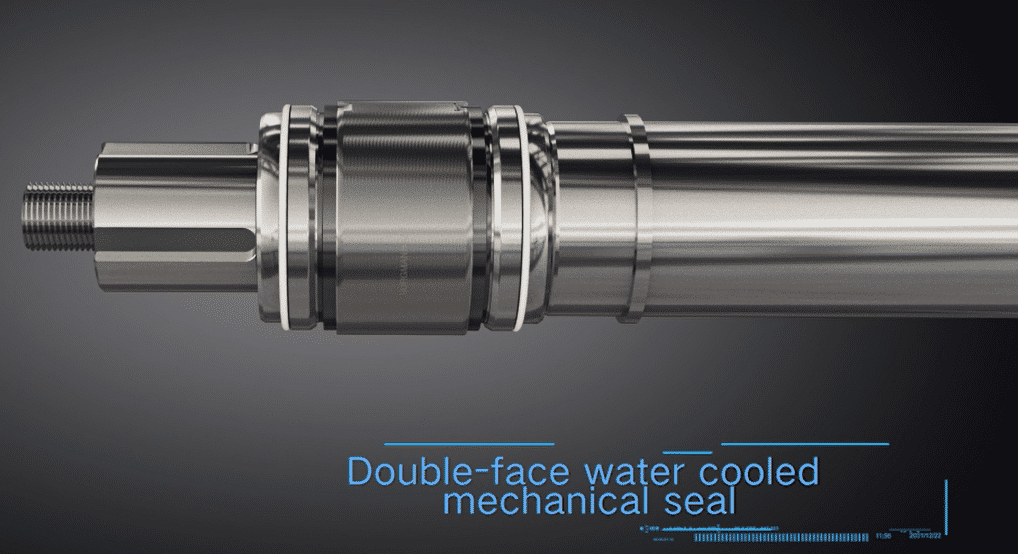

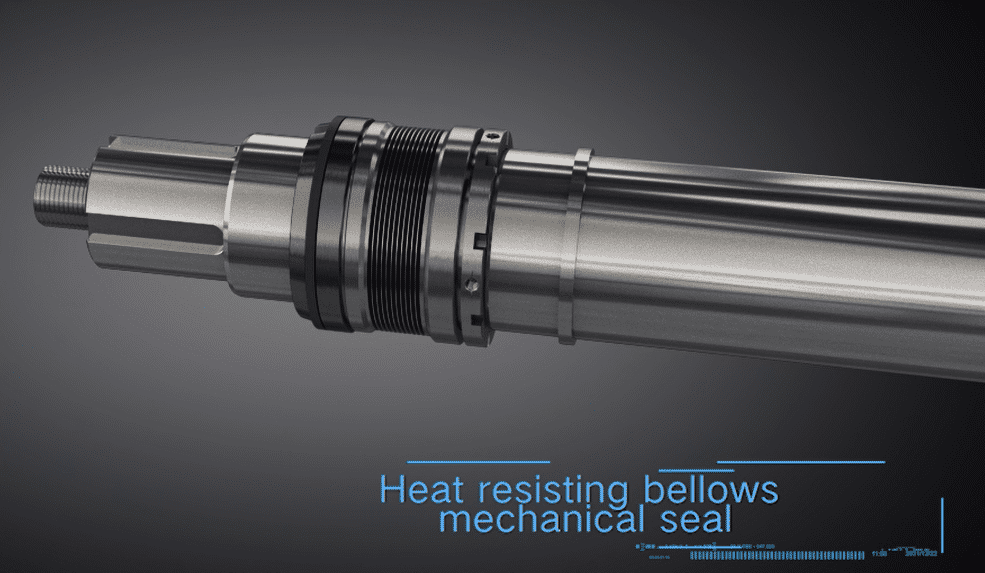

SEAL TYPES

According to the different characteristics of the medium, you can have the Single-face balancing mechanical seal, Double-face water cooled mechanical seal, Heat resisting bellows mechanical seal, etc. Targeted seal used ensures zero leakage. All these types can be universally interchanged.

Single-face balanced mechanical seal:Advanced balanced structure design, with self-adjusting function and long service life. Normal type to use. Typical pumped medium: tomato sauce, peanut butter, lotion, shampoo, syrup, yogurt ect.

|

Double-face water-cooled machine seal:Generally used with hostile media conditions i.e. high viscosity, high solid, hazardous or toxic fluids. Typical pumped medium:Abrasive Slurries, Chocolate, Hazardous Chemicals, PVC Paste, Photographic Emulsion, Resin.

|

Metal bellows mechanical seal:It has large elasticity, strength and rigidity, and can be used in situations where the pressure reaches 7Mpa. It is suitable for high and low temperature operations, and the temperature is -240 ℃ ~ + 650 ℃.

|

ROTOR TYPES

According to the different medium, the rotor designed has Single-wing, Double-wing, Tri-lobe, Four-impeller and Multi-impeller type, and all of these rotors can be universally interchanged.

Single-wing rotors

Used to transfer liquid medium with large particles. The rotor is not easy to damage particles. The shortage is high impulse, low pressure, small capacity, seldom to use.

|

Butterfly (Bi-wing) rotors

Used to transfer liquid medium with middle / small particles or high viscous liquid product. The rotor has low damage to the particles.

|

Tri-lobe rotors

The most widely used rotortype,suitable fortransferringvarious viscousliquid product, but not suitable forliquidwith particles, and it will have a certain crushing rate.

|

Multi-impeller rotors

Whenrotor impellerexceeds three,pump capacity will be reduced due to the increase of the rotor impellers.The more rotorimpellers, the lesscapacity,easy to damage the pumped medium.But higher stability.

|

TECHNICAL PARAMETERS

Pressure range:0-0.6Mpa

Displacement

|

RPM

|

Flow

|

Dis.Pre.

|

Power

|

Port size

| |

Model

|

(L/r)

|

(r/min)

|

(M³/h)

|

(Mpa)

|

(Kw)

|

(mm)

|

0.15

|

0-350

|

0-2

|

0-0.6

|

0.75-1.1

|

25

| |

25BV6-2

|

0.32

|

0-350

|

0-5

|

0-0.6

|

1.5-2.2

|

40

|

40BV6-5

|

0.65

|

0-350

|

0-10

|

0-0.6

|

2.2-4

|

50

|

50BV6-10

|

1.74

|

0-350

|

0-20

|

0-0.6

|

4-7.5

|

65

|

65BV6-20

|

2.48

|

0-250

|

0-30

|

0-0.6

|

5.5-11

|

80

|

80BV6-30

|

3.65

|

0-250

|

0-40

|

0-0.6

|

7.5-15

|

100

|

80BV6-40

|

4.60

|

0-250

|

0-50

|

0-0.6

|

11-18.5

|

125

|

125BV6-50

|

6.10

|

0-230

|

0-70

|

0-0.6

|

11-22

|

125

|

125BV6-70

|

7.63

|

0-230

|

0-80

|

0-0.6

|

15-30

|

125

|

125BV6-80

|

11.56

|

0-230

|

0-120

|

0-0.6

|

22-55

|

150

|

150BV6-120

|

14.22

|

0-230

|

0-150

|

0-0.6

|

37-75

|

150

|

150BV6-150

|

18.10

|

0-200

|

0-200

|

0-0.6

|

45-90

|

200

|

200BV6-200

|

22.92

|

0-200

|

0-250

|

0-0.6

|

55-110

|

250

|

250BV6-250

|

32.00

|

0-200

|

0-300

|

0-0.6

|

75-132

|

300

|

Pressure range:0-1.2Mpa

Model

|

Displacement

|

RPM

|

Flow

|

Dis.Pre.

|

Power

|

Port size

|

(L/r)

|

(r/min)

|

(M³/h)

|

(Mpa)

|

(Kw)

|

(mm)

| |

25BV12-2

|

0.15

|

0-350

|

0-2

|

0-1.2

|

0.75-2.2

|

25

|

40BV12-5

|

0.32

|

0-350

|

0-5

|

0-1.2

|

1.5-4

|

40

|

50BV12-10

|

0.65

|

0-350

|

0-10

|

0-1.2

|

2.2-7.5

|

50

|

65BV12-20

|

1.74

|

0-350

|

0-20

|

0-1.2

|

4-15

|

65

|

80BV12-40

|

3.65

|

0-250

|

0-40

|

0-1.2

|

7.5-30

|

100

|

125BV12-70

|

6.10

|

0-230

|

0-70

|

0-1.2

|

11-45

|

125

|

125BV12-80

|

7.63

|

0-230

|

0-80

|

0-1.2

|

15-55

|

125

|

150BV12-120

|

11.56

|

0-230

|

0-120

|

0-1.2

|

22-75

|

150

|

150BV12-150

|

14.22

|

0-230

|

0-150

|

0-1.2

|

37-90

|

150

|

200BV12-200

|

18.10

|

0-200

|

0-200

|

0-1.2

|

45-132

|

200

|

250BV12-250

|

22.92

|

0-200

|

0-250

|

0-1.2

|

55-160

|

250

|

Note: The above data is tested by water, only for reference. Please contact Bonve for model selection with your targeted application.

APPLICATIONS

Selection guideline

Customer information

| |||

Company

|

Atten:

| ||

Add.:

|

M:

| ||

Tel:

|

Fax:

| ||

Medium information

| |||

Your industry:__________ Medium name:__________

| |||

Medium feature:Corrosive[ ] Poisonous[ ] Sanitary [ ]

| |||

Medium viscosity:_________Cp Density:_________ Temp.:______℃ PH:_______

| |||

Duty

| |||

Capacity: Max.______ m3 /h Working:_______ m3/h Min.:_____ m3/h

| |||

Dis.pressure:Max.______Bar Working:_______Bar Min.:_____Bar

| |||

Suction pressure:Max.______Bar Working:_______Bar Min.:_____Bar

| |||

Vacuum:______ Mpa

| |||

Structure request

| |||

Jacket design:Yes[ ] No[ ]

| |||

Seal type:Mech. seal[ ] Packing[ ] Others[ ]

| |||

Driving type:Geared motor [ ] Belt reducer[ ]Step-less speed regulator[ ] VFD[ ]

| |||

Phase:______ V:_________ F:_________

| |||

Port direction:Inlet __________ Outlet____________

| |||

Inlet Dia.: Outlet Dia.:____________

| |||

Connection type:Flange[ ] Thread[ ] Clamp[ ]

| |||

Installation:Fixed[ ] Movable[ ]

| |||

Operating:Continuous[ ] Intermittent[ ]

| |||

Wetted material:SS304[ ] SS316[ ] SS316L[ ] Others________

| |||

Other request:_____________________________________

| |||

Ordered Qty.:

| |||

Being the Chinese leading manufacturer in pumps, Bonve Committed to offer high quality pumps to our clients with affordable price. The pumps we made not only durable but efficient, can definitely save a lot of your time and cost.

When you choose a Bonve pump, you not only get the high quality pumps, but also get the advantage of Bonve's engineering expertise and years of application knowledge in the food, chemical, pharmaceutical and cosmetics industries. We are looking forward to be your partner!

评论

发表评论